Site Map

Description

The most common applications are in products like cookware and stoves. The production process starts with stamping and stretching the raw materials into shape, followed by sandblasting treatment, and concludes with the spraying process.

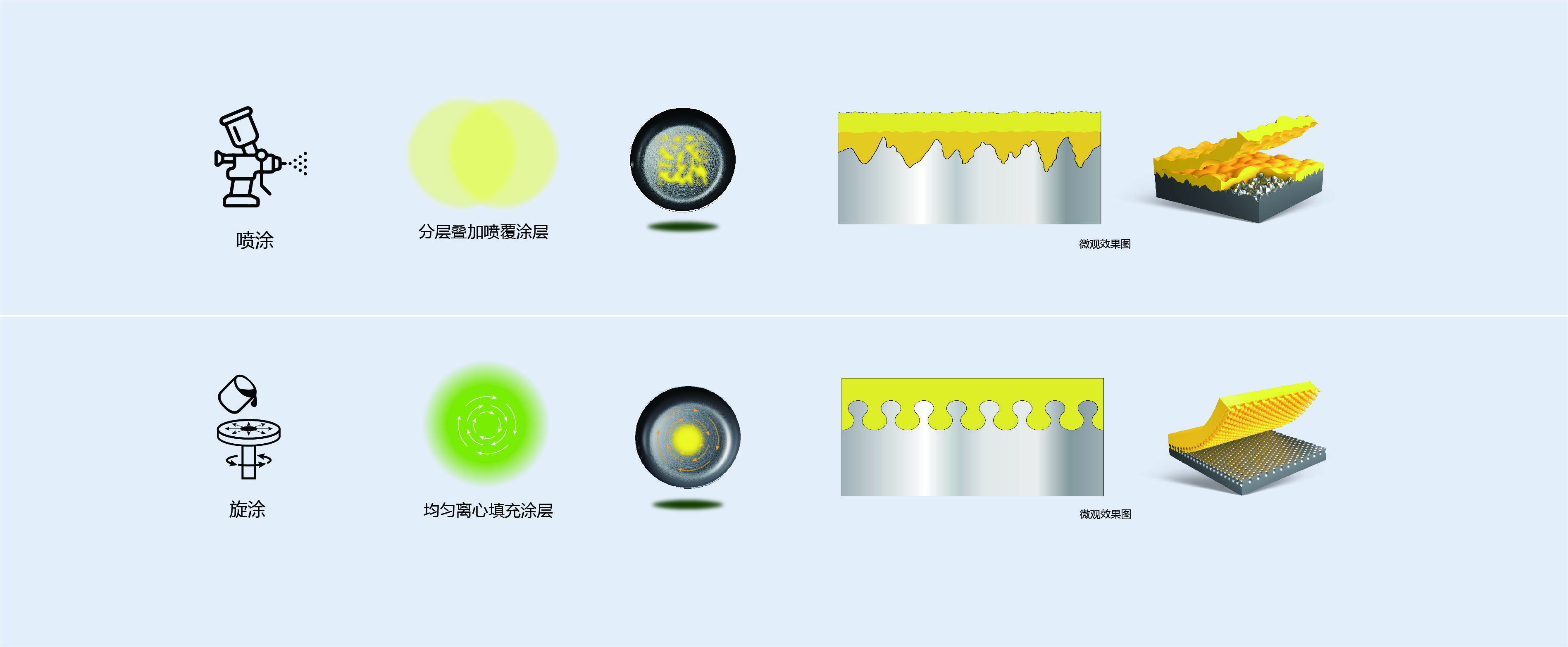

Products are sprayed on both the interior and exterior according to their shape. Although this method can achieve the desired coating effect, the process requires the addition of lubricating grease to the products during the stretching phase. After stretching, cleaning is necessary, and due to the varied shapes of the products formed by stretching, the paint utilization rate during the spraying process is low.

Type specification

2、It exhibits excellent corrosion resistance and can withstand temperatures up to 400°C, ensuring no metal ions leach out during cooking.

3、No binders are added; the coating composition has passed tests for compliance with relevant standards such as FDA, LFGB, and RoHS.

Technical parameters

1. Mortise structure, better adhesion: metal etching process can make the substrate form a mortise structure, which forms a mortise connection when combined with the painting, so that the painting bonding force is more excellent.

2. Zero pinhole, non-stick, more durable, more excellent corrosion resistance: Painting Process uses high-speed centrifugal force to quickly and evenly paint the painting on the substrate, forming a more dense zero-pinhole painting.

3. Airless painting, painting utilization rate of 99%: Compared with the traditional spray gun which requires high-pressure airflow to spray the painting to the surface of the product, the spin painting gun only relies on gravity to drip the painting to the center of the product, and the excess painting can be recycled.

4. Zero emission is more environmentally friendly and sustainable: Compared with traditional metal processing and painting processes, metal etching and Painting Processes are more environmentally friendly and sustainable. For example, the etching solution can be recycled and treated to reduce the impact on the environment; the painting materials used in the spin-painting process are also recyclable and environmentally friendly.