Site Map

Description

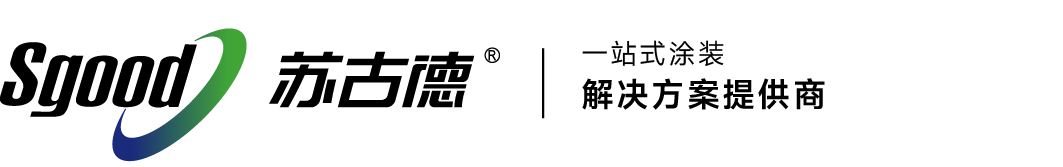

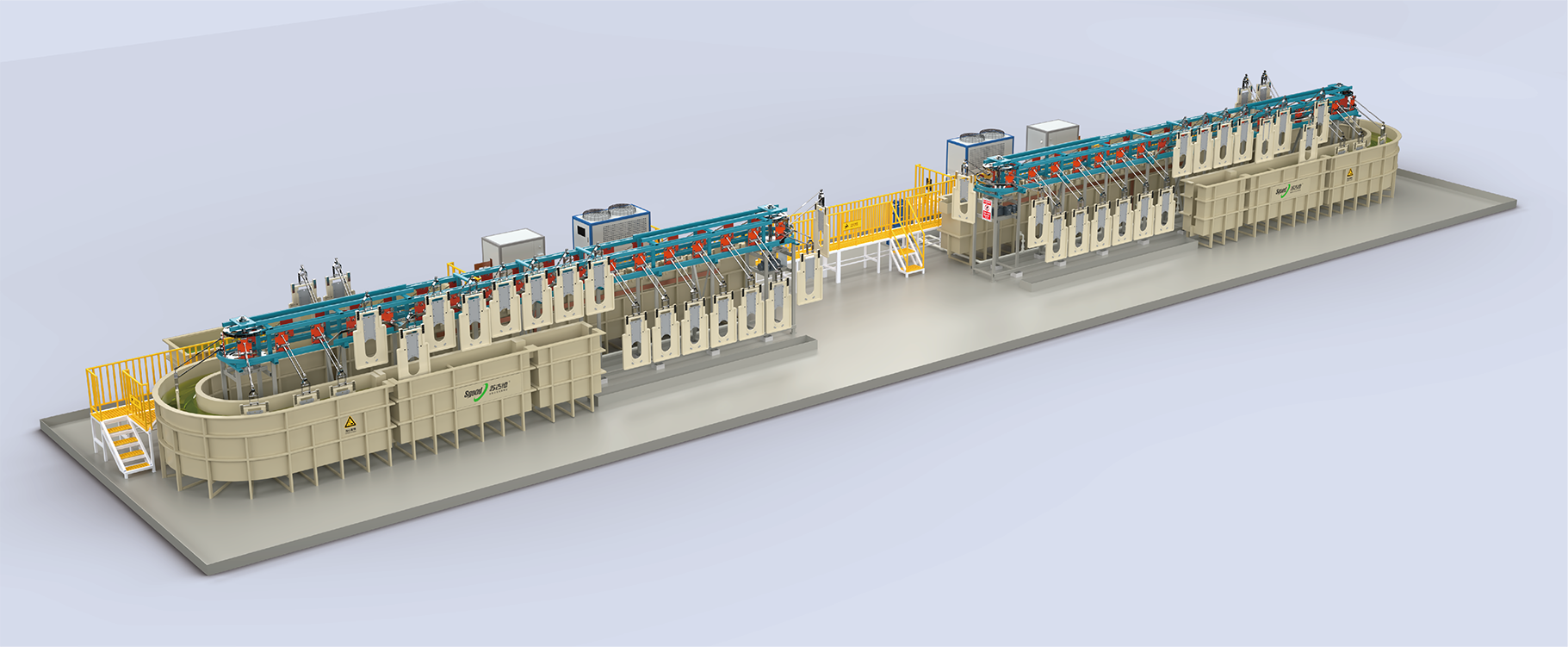

The etching line includes a spraying system, transmission system, clamping device, cleaning device, control system, and drainage system. During the etching process, no dust is produced, less labor is required, and the stability is better; the metal surface treatment is more refined, the metal surface is smoother, and the adhesion of subsequent paint is better; a vertical etching method is adopted, the etching speed is uniform, direct contact between the transmission device and the etching solution is avoided, the service life of the equipment is increased, and the maintenance cost is reduced.

Type specification

| Workpiece Size |

User Selected |

| Total Power of Equipment | 150KW(Customizable) |

| Equipment Dimensions | Length35mxWidth6mxHeight2.8m(Customizable) |

| Environmental Emission Standards | GB 16297-1996/GB 14554-1993 |

| Electrical and Dust Explosion-proof Standards | User Selected |

Technical parameters

Adhering to an environmental philosophy, we have created a model of energy-saving and efficiency. The equipment uses ammonium chloride solution as the etching solution, which simplifies the process and significantly reduces wastewater treatment costs, effectively saving production costs and achieving a win-win situation of green production and cost saving.