Description

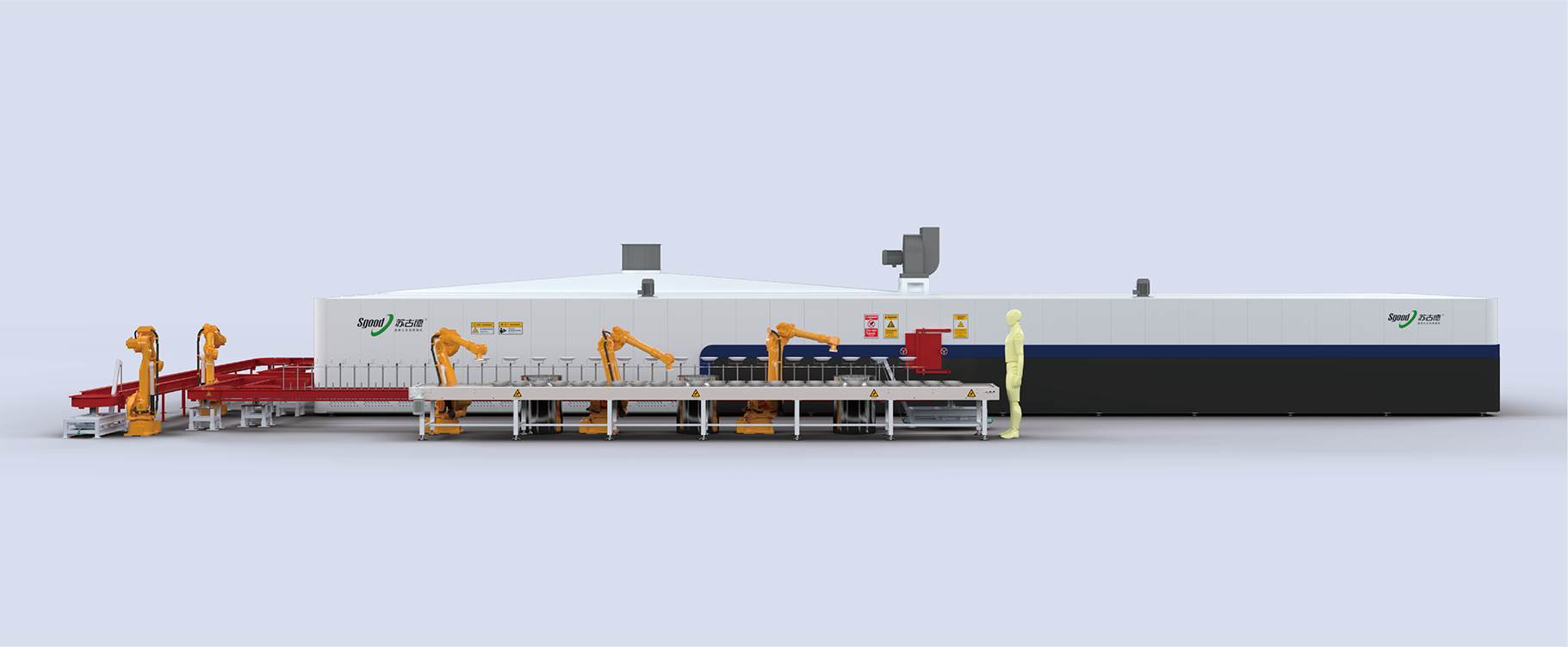

The fully automatic wet enameling production line includes automatic piece picking by robotic arm, dipping and wet enameling, a preheating section for products, automatic piece transfer by robotic arm, an 850℃ high-temperature enameling and sintering section, and a quenching cooling device. The preheating section utilizes the high temperature from the sintering section for preheating, achieving heat recovery and reducing waste.

Type specification

| Workpiece Size |

User Selected |

| Total Power of Equipment | 630KW(Customizable) |

| Equipment Dimensions | Length21mxWidth10mxHeight2.7m(Customizable) |

| Environmental Emission Standards | GB 16297-1996/GB 14554-1993 |

| Electrical and Dust Explosion-proof Standards | User Selected |

Technical parameters

By employing 6-axis robots for slinging and transferring operations, we can not only significantly reduce labor costs but also effectively enhance production efficiency and product quality. Moreover, the heat recovery design of the sintering furnace not only reduces energy consumption but also lowers production costs, achieving the dual goals of high efficiency and environmental protection.